From Platform to Impact: Key Reflections from SAKO 2026

As a Silver Sponsor, Addovation had the opportunity to engage closely with customers, partners, and IFS leadership at SAKO 2026 in Dallas, Texas.

Gro-Anita Fjeldheim

Sales Manager Addovation

One message stood out clearly above the rest: the industrial software conversation is changing. The discussion has decisively shifted toward real operational impact, how technology improves uptime, efficiency, resilience, and sustainability in day-to-day industrial operations.

Industrial AI as an enabler of operational excellence

Rather than positioning AI as a standalone innovation, IFS presented Industrial AI as an embedded capability, deeply integrated into IFS Cloud and grounded in industry-specific knowledge and operational data. The ambition is not experimentation, but execution: using AI to support better decisions, optimize planning, improve maintenance strategies, and enhance service delivery.

This marks a shift from generic AI tooling toward solutions designed to address real industrial complexity, where reliability, safety, and performance are critical.

One platform, purpose-built for industries

IFS Cloud continues to be positioned as a single platform, but with a clear emphasis on ready-to-use, industry-specific solutions. The intent is to reduce customization, accelerate adoption, and shorten the path from implementation to value. In practice, this means less time spent configuring systems and more time realizing measurable outcomes.

Sustainability moves into operations

Another notable theme was the evolution of sustainability from a reporting exercise to an operational discipline. Within asset-intensive and service-driven industries, sustainability is increasingly tied to how assets are operated, maintained, and supplied. Embedding sustainability into core processes enables organizations to make more responsible decisions without compromising performance or profitability.

Service and asset management as strategic value drivers

Service and asset management were consistently highlighted as key contributors to business value. Improved uptime, safer operations, lower lifecycle costs, and better customer outcomes are no longer seen as by-products of digitalization—but as primary strategic objectives enabled by modern enterprise solutions.

Lower friction, faster value

Finally, IFS emphasized a clear ambition to simplify adoption and reduce friction—both in initial implementations and ongoing upgrades. Shorter time-to-value and easier lifecycle management are becoming essential as organizations seek agility without operational disruption.

Key takeaways

- The industry is moving from platform-centric discussions to outcome-driven execution

- Industrial AI is embedded, practical, and designed for real operational use

- Industry-specific solutions enable faster adoption and measurable value

- Sustainability is becoming an operational capability, not just a reporting requirement

- Service and asset management are central to efficiency, resilience, and growth

- Simplicity and speed are critical for long-term digital success

At SAKO 2026, IFS made it clear that the next phase of industrial digitalization will be defined not by technology alone, but by its ability to deliver sustained impact where it matters most: in operations.

Read more blogs

Manufacturing Highlights in 25R2 How Addovation Helps You Maximize 25R2 At Addovation, we go beyond

What IFS Quality Control Delivers IFS Cloud brings all quality steps together — from incoming

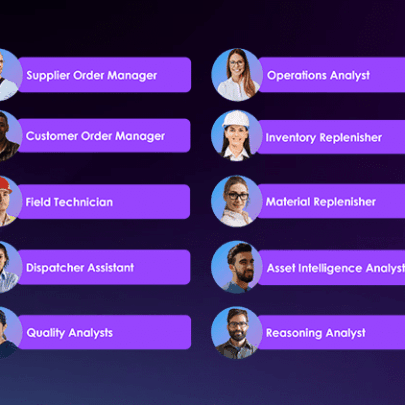

IFS calls it “a digital workforce for industrial operations.” We call it a practical way to take the friction out of everyday processes.