.

Unlocking the true value of digital technology in manufacturing

The speed at which digital technology advances and the way it can disrupt entire markets is truly mindboggling. Why do I think that?

Written by Maggie Slowik, Global Industry Director for Manufacturing at IFS. First published December 6th, 2021 at blog.ifs.com

For almost 5 years, I was a manufacturing analyst at IDC and worked with leading software providers and manufacturers to help develop and drive their digital transformation strategies, so I’ve seen the impact first-hand

Isn’t it all just buzz words?

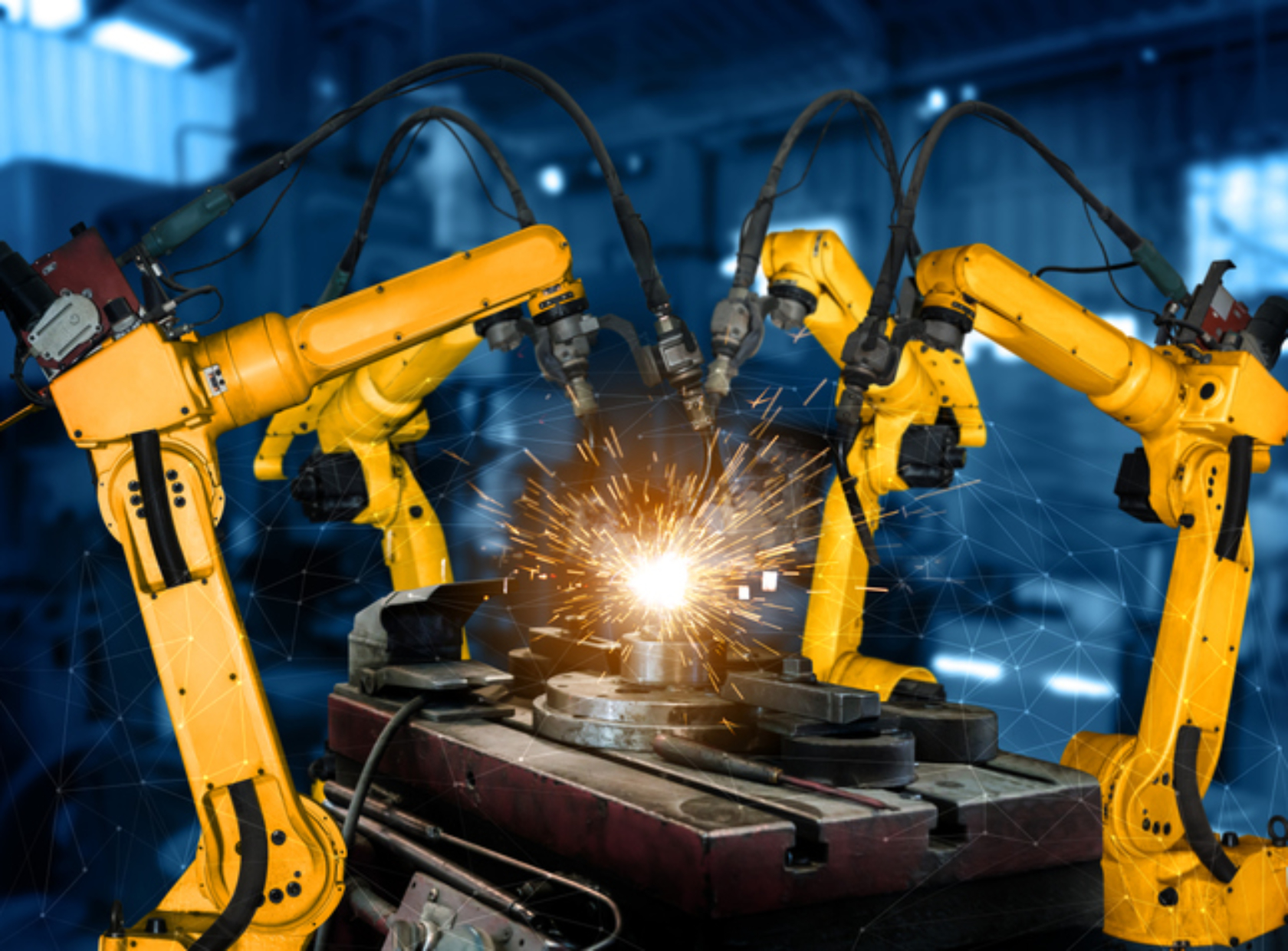

Cloud computing, IoT, Artificial Intelligence, robotics, and 3D printing, augmented reality, and more recently, the digital twin and the digital thread, are nothing new. But who’d have thought that augmented & mixed reality would be guiding technicians in remote locations, or 3D printers producing components in the automotive industry to overcome supply chain challenges?

The technology market for industry is huge. Today’s manufacturers, to a greater or lesser extent, have made investments in targeted technologies to improve operational efficiency and productivity, reduce cost, accelerate speed to market and customer acquisition rates, and drive innovation. In fact, IDC research shows that digital investments have a direct impact on a company’s profit and revenue performance, because not only will digital companies leverage their new capabilities to achieve efficiencies but, more importantly, use them to drive new business opportunities and models.

The COVID-19 pandemic has accelerated the adoption of digital transformation among manufacturers worldwide. It was been a wake-up call for those who, up to this point, have made little or no investments; even these organizations now recognize the strong correlation between digital tools and increased productivity, efficiency and resilience, and that without it, they would fall behind in a world of increasing competition fueled by digital disruption.

And yet, while the potential of digital technologies has only started scratching the surface, we need to be very careful about putting it into the right perspective when making investment decisions.

Technology for technology’s sake?

As already mentioned, the technology supply market is not only growing, but also proliferating, and quite frankly, can be overwhelming for those who are technology influencers, decision-makers or buyers. I remember a visit to Hannover Messe four years ago, where blockchain was a buzzing theme, 3 years later, it was 5G. But how much should manufacturers invest in these new technologies, and do the use cases stack up?

While the potential impact of digital technology is promising, it’s paramount that companies first look at the business problem they’re trying to solve and visualize the role they want to play in the market. In other words, rather than taking a technology-first approach, the focus needs to be on transforming the business itself. These were the kinds of conversations I used to have with manufacturers in my previous role. We would then look at the use case trajectory, starting with the aspirational vision, and then retro engineer back to the ‘quick win’ use cases, building up further business cases from there. Still, it’s difficult not to get distracted by the ‘noise’ created by a technology market that is constantly pushing innovation.

Another key success factor, all too often underestimated, is the people aspect. Although IT plays an important role in driving the digital transformation strategy, implementing and adapting to the big changes that come as a result, falls on the employees. When people question their value, perhaps fear that their jobs are at risk, or don’t understand the benefits that new technologies can bring, IT leaders will feel the pushback. Manufacturers are very familiar with this issue; in my conversations with IT leaders, I often heard that the more seasoned generation of workers in particular, used to operating in certain ways, would question and potentially resist adopting new digital tools. This is all too often down to a lack of understanding caused by insufficient top-down communication, engagement, and empathy. In such cases, employees could even turn into innovation “opponents”.

A customer-centric approach to innovation

I recently joined IFS as Industry Director for Manufacturing, where I’m actively involved in shaping the future direction of our solution by acting as the eyes and ears of our customers. One of the aspects that attracted me to IFS in the first place was its customer-centric approach to technology innovation.

By this I mean that we actively listen to our customer’s challenges, feedback and suggestions, via a number of platforms, and incorporate them into our roadmap. So ultimately our customers are influencing and driving the enhancements to our solution.

But even more unique (says the former manufacturing analyst) is the way IFS brings innovation to customers. Yes, there’s the IFS Cloud evergreen approach, which means customers always have access to the very latest software versions, and avoid the distraction, cost, and complexity of major upgrades. But at the heart of IFS’ customer-centric approach is how our R&D team embeds enhancements and innovations within the solution – including artificial intelligence and machine learning – with users not necessarily knowing it’s even there. This may be stating the obvious, but from a user perspective, not all innovation is necessarily welcome, and if we can’t make the experience simpler, more effective and delightful, the adoption of technology is at risk of failing.

I’ll talk about one of our newest customer-centric innovations, intraday planning, in greater detail in one of my next blogs, but for now, I’ll finish by saying that a technology-first approach won’t necessarily solve all of your business problems. It couldn’t be a more exciting time for manufacturers, given the potential of digitalization, however technology investments must be made with a business- and people-first approach, otherwise they could quickly become expensive, potentially wasted investments.

If you’d like to read more about digital transformation in manufacturing why not have a look at this IFS eBook, Bring Digital to Life in Manufacturing.